| This site uses cookies to enhance our services. By continuing to browse the site, you agree to our Cookies Policy. |

| This site uses cookies to enhance our services. By continuing to browse the site, you agree to our Cookies Policy. |

| Emissions from Marine Engines and NOx Reduction Methods |

The new IMO Tier III regulation, which appearence in 2016, will further restrict the emission limits in ECAs (Emission Control Areas). In this case they want to establish a 80% reduction of NOx emissions compared with the IMO Tier I regulations in ECAs, whereby the sulfur in these areas will be 0.1% from 2015.Injection and combustion simulation (temperature range) in a motor MAN D2840LE. Nowadays, diesel engines power more than 90% of the world’s oceangoing ships. Diesel engines have replaced most of the steam turbine systems that were dominant in the 1940s. Most marine fuels are residual heavy fuel oils, which are cheap but contain an important quantity of pollutant substances. Since the 1973 fuel crisis, crude oils have been processed using secondary refining technologies to extract the maximum quantity of refined products (distillates). As a consequence, the concentration of contaminants such as sulfur, ash, asphaltenes, and so on in the residuals has increased. Diesel engines operate with air excess. Fuel is injected at high pressures into air which has been compressed by the moving pistons. This compression raises the temperature of the air sufficiently to cause the fuel to ignite. Combustion proceeds around the periphery of the fuel spray at temperatures around 2000°C. Combustion products have an important percentage of oxygen (O2) and nitrogen (N2). Other emissions from diesel engines are nitrogen oxides (NOx), sulphur oxides (SOx), carbon monoxide (CO), unburnt hydrocarbons (HC), particulates, and so on. Nitrogen oxides are more important in diesel engines than gasoline engines due to the nitrogen and oxygen from the air excess. Ship emissions may be transported hundreds of kilometers inland. Schwartz (1989) indicated that the median transport velocity of SOx and NOx is about 400 km per day, and the mean residence times of 1 to 3 days, indicating mean transport distances of 400 to 1200 km. Nevertheless, several posterior studies showed that some 70% or more of emissions by international ships occurs within 400 km of land, Corbett et al. (1999); Endresen et al. (2003); Eyring et al. (2005). Oxygen, nitrogen and water vapor are not toxic. Carbon dioxide is not toxic either, but it contributes to the greenhouse effect (global warming). Nevertheless, it is an inevitable product of combustion of all fossil fuels, see reaction (1). Recent studies have estimated that 2.7% of global CO2 emissions are attributable to ships, Eyring et al. (2005), estimating CO2 emissions from shipping of the same order as CO2 emissions from aviation. Speed reduction is an operational measure which offers significant CO2 reductions. A 10% speed reduction gives 20% reduction in fuel consumption over the same distance, Kuiken (2008). The global and regional impact of air pollution from ship engines has not been addressed until recently, by agencies as Environmental Protection Agency, European Commission and International Maritime Organization. The U.S. Environmental Protection Agency (EPA or sometimos USEPA) is an agency of the United States federal government created for the purpose of protecting human health and the environment by writing and enforcing regulations. The European Commission is the executive body of the European Union responsible for proposing legislation, implementing decisions, upholding the Union’s treaties and day-today running of the EU. In 2002, the European Comisión adopted a European Union strategy to reduce atmospheric emissions from ships. At the international level, the International Maritime Organization (IMO) is an agency which develops and maintains a develop and maintain a comprehensive regulatory framework for shipping and its remit today includes safety, environmental concerns, legal matters, technical co-operation, maritime security and the efficiency of shipping. In 1973, IMO adopted MARPOL 73/78, the International Convention for the Prevention of Pollution From Ships. Marpol 73/78 is one of the most important international marine environmental convections. It was designed to minimize pollution of the seas. Annex VI of the MARPOL convention regulations for the prevention of air pollution by ships, setting limits on sulphur oxide and nitrogen oxides. Concerning SOx, it limits the sulfur content in fuels. Concerning NOx, it establishes a curve which indicates the maximum allowable NOx emission levels related to engine speed, applicable to marine diesel engines built after 2000, 2011 and 2016.

PRIMARY MEASURES:

Decrease of injection duration, delay of start of injection and pre-injection: A delayed injection leads to lower peak pressures and therefore temperatures. Retarding injection timing also decreases the amount of fuel burnt before peak pressure, thus reducing the residence time and degree of after-compression of the first burnt gas. Okada et al. (2001) applied an injection timing retard of 7º to the MAN B&W 4T50MX research engine and they obtained a reduction of NOx by about 30% and an increased in consumption by about 7%. Li et al. (2010) also analyzed the influence of the fuel injection advance angle on nitrogen oxide emissions. Moreno Gutiérrez et al. (2006) studied the consumption and NOx emissions in several marine engines with different injection timings. Al-Sened and Karini (2001) found that pre-injection can be used to shorten the delay period and thus decrease temperature and pressure during the early stages of combustion, resulting in reduced NOx. Besides, they found a decrease in particulares emission. Fankhauser and Heim (2001) also found that pre-injection reduces NOx with a slightly increase in fuel consumption. They studied a Sulzer RT-Flex common rail engine. With triple injection, the fuel charge is injected in separate, short sprays in succession. UIT sequential injection, each of the three nozzles in a cylinder is actuated with different timing. The results showed about 30% NOx reduction with about 8% increase in fuel consumption. Kontoulis et al. (2008) studied numerically the effect of multiple injection strategies in the Sulzer RTA58T marine engine. They demonstrated that, by adding a pilot injection, appropriately timed, it is possible to reduce NOx emissions and save fuel at the same time, particularly 1.7% of fuel reduction. Panagiotis et al. (2009) also studied numerically the multiple injection in a marine engine, the Sulzer RT-flex58T-B and they also got a decrease in NOx and consumption. Scavenging air cooling: Scavenge air cooling aims to reduce the maximum temperature in the cylinder by lowering the temperature before compression. Holtbecker and Geist (1998) showed that for every 3% reduction, NOx may decrease by about 1% in the Sulzer RTA84C. Sencic (2010) developed a CFD (Computacional Fluid Dynamics) model to simulate the reduction in NOx emissions with reducing the scavenging air temperature. Besides, he studied the exhaust gas recirculation and several injection patterns. He studied the MAN 6S50Mc and Wärtsilä RT-flex50 marine engines. Water injection: There are three possibilities: fuel-water emulsion, direct water injection or humidification. Introduction of water into the combustion chamber reduces NOx formation due to the increase in the specific heat capacity of the cylinder gases (water has higher specific heat capacity than air) and reduced overall oxygen concentration. The influence of water varies with engine type, but generally 1% percent of water reduces NOx by 1%, Woodyard (2009). Exhaust gas recirculation (EGR): Exhaust gas recirculation lowers the combustion temperature, and consequently NOx, by reticulating exhaust gases to the charge air. This reduces NOx formation due to the increase in the specific heat capacity of the cylinder gases (water has higher specific heat capacity than air) and reduced overall oxygen concentration. Holtbecker and Geist (1998) found 22% NOx reduction with 6% EGR in the 4RTX54 research engine. However, they postulated that EGR increases smoke, hydrocarbons and CO. Millo et al. (2011) analyzed EGR combined with a Miller cycle in a Wärtsilä W20 marine engine. They obtained NOx reductions up to 90%. Miller cycle: In four-stroke engines, the Miller cycle uses a higher than normal pressure turbocharge. The inlet valve is closed before the piston reaches bottom dead center on the intake stroke. The charge air then expends inside the engine cylinder as the piston moves towards bottom dead center resulting in a reduced temperature. Schelmmer-Kelling and Rautenstrauch (2001) applied Miller cycle to a Caterpillar engine by earlier closing of inlet valves and slightly increased charge pressure and found that NOx is reduced but smoke is increased.

SECONDARY MEASURES: The most employed secondary measure in marine

engines is SCR (Selective Catalytic Reduction). SCR involves mixing of ammonia

with the exhaust gas passing over a catalyst. The ammonia is usually supplied

as a solution of urea in water. In order to avoid premature damage of the

catalyst system, it is necessary to employ low sulphur fuels.

Para reducir los óxidos de azufre, existen

unos equipos llamados desulfuradores. Al igual que los SCR, el funcionamiento

se basa en inyectar una sustancia que reaccione químicamente con el gas

contaminante y el compuesto químico formado sea un gas nocivo o un sólido que

precipita en un recipiente habilitado para ello. Esta medida es muy utilizada

ya que es muy complicado y costoso reducir las emisiones de los óxidos de

azufre utilizando medias primarias, al contrario de lo que se hace con los óxidos

de nitrógeno.

According to MAN B&W (1997) and Wärtsilä (2002), SCR can remove more of 90% of NOx. Jayaran et al. (2011) studied SCR in the MAN B&W 7L32/40 marine engine. NOx emissions for this engine vary from 15 to 21.1 g/kW-h for heavy fuel oil and 8.9 to 19.6 g/kW-h for marine distillate oil. Applying SCR, they reduced the NOx emission factor to less than 2.4 g/kW-h, but it increased the PM emissions by a factor of 1.5–3.8.

CONCLUSON:

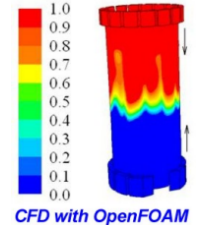

Due to the lean combustion in diesel engines, these have relatively low emissions of carbon monoxide and hydrocarbons. However, nitric oxides and particulate are more important. Due to the efforts to reduce NOx and other pollutants from ships, this paper offers a state of art of the NOx reduction methods. It was shown that there are primary and secondary measures. The well-known drawbacks in employing catalytic converters in ships, mainly the necessity of a reducing agent together with the additional space required for the catalytic reactor, make them barely acceptable to marine diesel engine users. Consequently, primary reduction measures are the first choice for to reduce the formation of pollutants on board ships. EGR and water addition are the most employed primary measures. Both can strongly reduce NOx, but they increment hydrocarbons and CO emissions. Concerning SOx, chemical and washing/scrubbing desulphurization process are complex, bulky and expensive for shipboard applications. The most economical and simplest approach to reduce SOx is thus to use low sulphur fuels.  Currently it is possible to analyze the emissions from engines using CFD (Computational Fluid

Mechanics) and can perform simulations of different injection patterns, humidification load, change of distribution diagrams, Miller cycle, exhaust gas recirculation,

and general any operating

parameter of the engine can be

simulated and tested virtually

by computer, with corresponding savings

of time and money before performing the actual tests and subsequent modifications to the engine. The utility of modern modeling

tools and simulation software CFD are now indisputable,

allowing to test virtually different models or designs before industrial prototype manufacture, providing this methodology, enormous

advantages and benefits cost savings in prototyping and shortened time in

product development

COURSES RECOMMENDED:  CFD with OpenFOAM online course CFD with OpenFOAM online course

LINKS:

- Revista Journal Of Maritime Research; Emissions from Marine Engines and Nox Reduction Methods - MAN Diesel & Turbo - HOMEPAGE

- Grupo de Innovaciones Mariñas de la Universidad de La Coruña.

|

| Published 2014-04-11 12:04:42 by Isabel Lamas |

| Twittear |